One of the most important suppliers of the chip industry reportedly said that the multi-billion-dollar expansion plans of chipmakers will be limited by the shortage of key equipment in the next two years, which will it makes it difficult for the supply chain to improve production efficiency.

The warning came from Peter Wennink, chief executive of ASML. The company dominates the global market for lithography machines, which are used to manufacture advanced semiconductors.

Join tip3x on Telegram

“There’s going to be a shortage next year and the year after, and this year we’ll ship more machines than last year, and next year we’ll have more machines than this year. But if we look at the demand curve, that growth is still a lot, ” Wenningk said. We do need to increase capacity by more than 50%. It all takes time.”

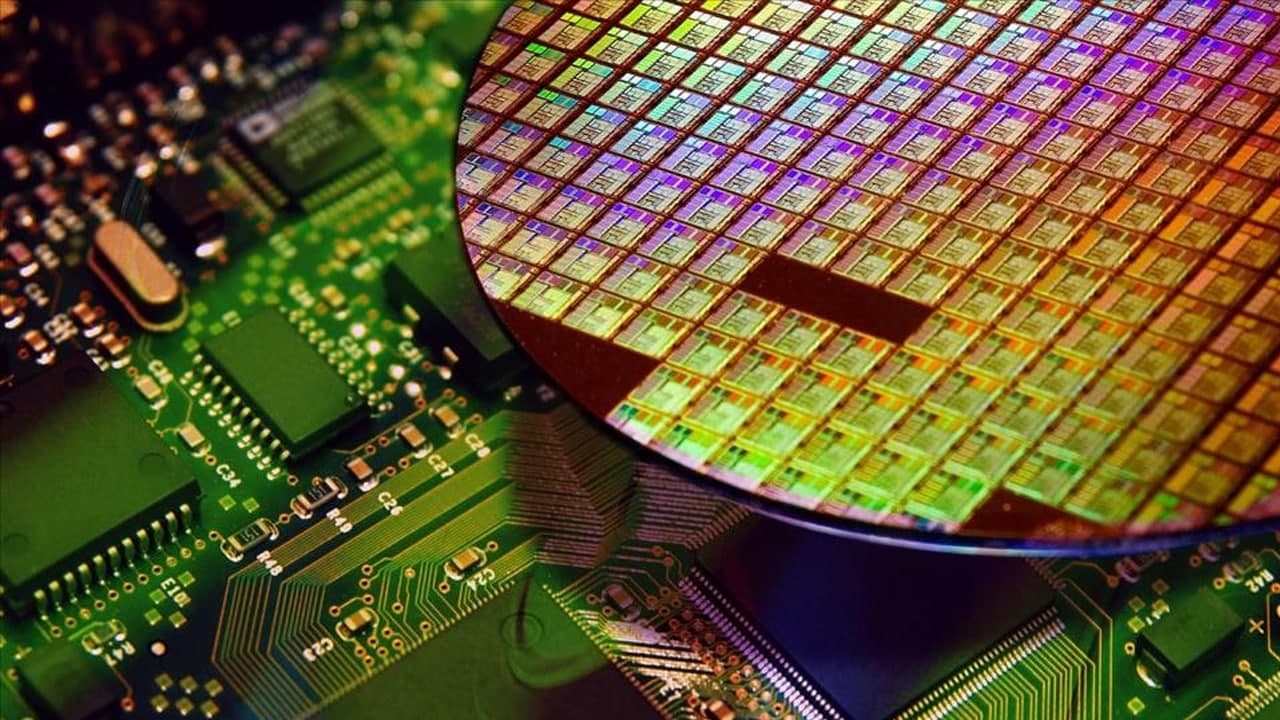

Moreover, machines made by ASML are used to etch circuits on silicon wafers. “ASML is one of the most critical companies in the semiconductor supply chain, a printing press for silicon chips,” said Richard Windsor, a technology analyst at Radio Free Mobile.

Wenning said ASML is evaluating with suppliers how to increase capacity. He said it was unclear how much investment would be needed. ASML has 700 product-related suppliers, of which 200 are key suppliers.

Wenning said ASML is evaluating with suppliers how to increase capacity. He said it was unclear how much investment would be needed. ASML has 700 product-related suppliers, of which 200 are key suppliers.

His remarks come as the semiconductor industry accelerates investment in new products to meet a global chip shortage and surging demand. Analysts expect the market to double to $1 trillion by 2030.

Intel Corp said last week it would invest about 33 billion euros in manufacturing and research in Europe. By 2020, the investment will increase to 80 billion euros, depending on demand. The company also announced plans to invest $40 billion to expand its chip-making operations in the United States.

The U.S. chipmaker is racing to catch up to industry leader TSMC, which will invest more than $100 billion over the next three years. In addition, Samsung has said it will invest $150 billion to expand production by 2020. This is part of an expected investment of 510 trillion won ($421 billion) by more than 150 South Korean companies, government data shows.

Furthermore, the United States and Europe also plan to spend tens of billions of dollars in support of chip manufacturing to reduce their reliance on Asian manufacturers.

Intel CEO Pat Gelsinger acknowledged that equipment shortages have challenged the company’s expansion plans. He said he had been in direct contact with Wenninger about the supply shortage and that Intel had sent its own manufacturing experts to the company to help speed up production.

“Today, it’s a restriction,” he told the Financial Times but stressed that there was still time to address the issue. It took two years to build the outer frame of the chip factory. “Then in the third or fourth year, you need to start filling it with equipment,” he said.

Wenninger agreed that there is still some time to expand the supply chain’s capacity, as many new manufacturing facilities will not be commissioned until 2024. But this thing is not simple. For example, the most complex part of an ASML device is a lens made by the German manufacturer Carl Zeiss

“They need to make more lenses,” says Wenning. But first, the company has to “build clean rooms, they need to start applying for permits, they need to start organizing new factories. Once the factories are ready, they need to order manufacturing equipment. They need to hire people and then they need to. All in all, it takes more than 12 months to make this lens.”